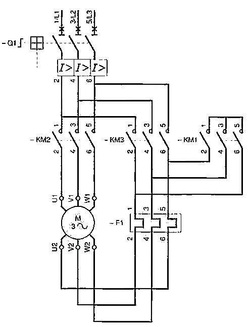

( I believe what happened, was the 3 phases were not correct on the line leads to delta leads. They must switch phases from U1/U2, V1/V2 & W1/W2. If you look at the diagram, you will see line one feeds U1, then goes down to the delta side, and feeds V2, opposite phases. This is why the motor stopped when it switched to delta run.)

Checked leads, thought about it, called for the wiring diagram for the motor, then it hit me. Switch the contactor wires, feeding the delta motor connection, and the line leads. It worked! I was stoked! I had been worrying over this now for at least 2 hours! Hooking up, checking, changing! Looking for smoke...Yikes! I won't let that happen, I always have my amp probe, monitoring motor current. If it goes high for over 1 second after start, I hit the stop! It started up, pulled 40 amps to get going, then dropped right back to 2.4 amps. Sweet. Then, switched to delta connection, and current went up to 7.5 amps, ready to shave some wood! When it's belted up to the cutting spindle, it will pull up to 24 amps while cutting wood. It's done, and chalked up to another lesson learned. I also reset the motor over current relay to 24 amps, motor nameplate amps.