Another fantastic shot of the San Juan mountains this morning! It's a bluebird day here in Colorado today. I had to stop and take this photo, even though I drive by this scene everyday, today it looked particularly great!

| Protek Electric |

|

Another fantastic shot of the San Juan mountains this morning! It's a bluebird day here in Colorado today. I had to stop and take this photo, even though I drive by this scene everyday, today it looked particularly great!

0 Comments

Click on the link to see my 'bear in my yard' video. Pretty silly.

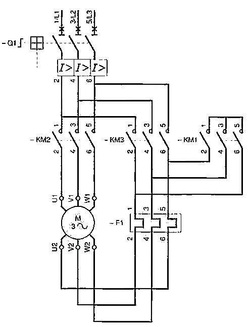

https://www.youtube.com/watch?v=qQTOlMegKzc  Well, today is just a good day to be out in the woods. I've been out walking around, looking at the new things coming up, and just enjoying the sun and time of year. It could not be nicer today! No jobs yet, but maybe by the end of the day, I'll have something to fix. Yesterday, I had two hard jobs to do. One was a VFD drive running a big irrigation system that would not start. Got it going pretty quickly, but it was challenging. I didn't know the system well at all, so I had to start at the beginning, trace through all the circuits that connected to the drive. I found a float switch that was stuck. I hit it with a stick, and it took off. The other job was a motor hook up for a domestic water system. It was really hard, just because I could not see the connections on the back of the motor! I had to use a mirror and fight it all the way! Got it going though!  I had to hook up a new motor for a planer in a carpenter shop. The circuit that does this is shown at left. New motor, but different from the old one. Used the motor diagram for connection, hooked up the power leads, and hit start. Motor started and ran, but timed into 'delta run' contactor, and it stopped. ???? ( I believe what happened, was the 3 phases were not correct on the line leads to delta leads. They must switch phases from U1/U2, V1/V2 & W1/W2. If you look at the diagram, you will see line one feeds U1, then goes down to the delta side, and feeds V2, opposite phases. This is why the motor stopped when it switched to delta run.) Checked leads, thought about it, called for the wiring diagram for the motor, then it hit me. Switch the contactor wires, feeding the delta motor connection, and the line leads. It worked! I was stoked! I had been worrying over this now for at least 2 hours! Hooking up, checking, changing! Looking for smoke...Yikes! I won't let that happen, I always have my amp probe, monitoring motor current. If it goes high for over 1 second after start, I hit the stop! It started up, pulled 40 amps to get going, then dropped right back to 2.4 amps. Sweet. Then, switched to delta connection, and current went up to 7.5 amps, ready to shave some wood! When it's belted up to the cutting spindle, it will pull up to 24 amps while cutting wood. It's done, and chalked up to another lesson learned. I also reset the motor over current relay to 24 amps, motor nameplate amps.  It's that time of year! I love going out to the hay fields to work on pivots! It's so green and nice. I had a good one yesterday, a Lockwood pivot had a failed safety circuit. Checked each tower and they all looked good, but no safety circuit return to the control panel! Finally checked the collector rings, and found it! The brush was oxidized on the low voltage safety circuit. It's only about 16 volts coming back, and a little oxidization will not conduct. A little sandpaper and it's good to go! Interesting call yesterday to a big carpenter shop. I had an Italian made planer that was tripping the main breaker feeding the machine the instant you pressed the start button to bring on the planer motor. I felt that it was most likely a grounded motor winding, and it did show a ground. But I went through the connections and metered it all out, but I didn't see the normal reading you would see on a regular 3 phase motor. The reason? It was wired as a 'wye/delta', soft start circuit. This circuit applies the voltage to the motor windings in a 'wye' connection during initial starting, then after a 3 second time delay, connects the motor as a 'delta' connection, or full line voltage. This can be a bit tricky if you're not used to seeing this. At first, I checked things with my meter and felt that, due to the ground reading' it was the motor for sure, and made the call, billed them, and left.

On the drive home, it was just nagging me about the readings I saw with my meter. I began doubting my diagnoses. This could have been a costly mistake for my customer if I was wrong. A $1000 dollar motor shipped, plus shipping costs! I got home and decided to go all the way back, to Mancos, to re check the circuit! I got back to the shop and devised a test for the control contactors by jumping out a couple circuits, and was able to press the start button, and not actually apply power to the motor, but just let the control bring on the contactors to simulate a normal start. Everything checked out perfectly! I had made the right call after all! I also learned a great deal about wye/delta starting for large, 3 phase AC motors! A good day after all. |

Craig's blog

The life & times of my electrical world! Archives

March 2016

|